Built for Tough Jobs: Hoses for Construction Machinery

- jumi

- 2026-01-29

- 21

In heavy construction machinery, durability, reliability, and performance are essential. Whether you are operating excavators, wheel loaders, cranes, or graders, every component of your machinery contributes to efficiency and productivity. Among these components, one of the most critical yet often overlooked is the construction machinery hose. This small but key part ensures hydraulic systems operate smoothly, controls fluid transfers, and withstands the harshest job site conditions.

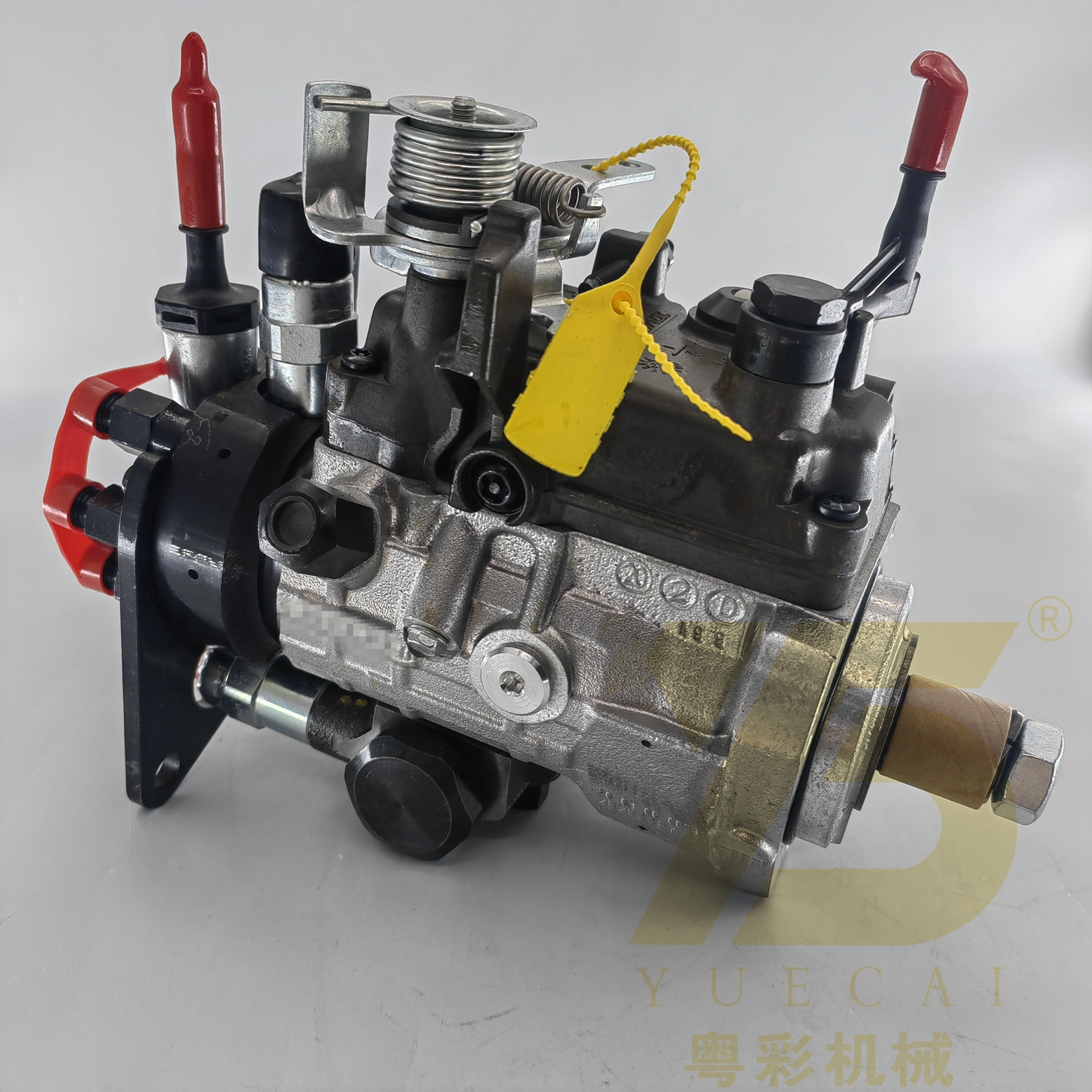

For operators and fleet managers, selecting the right hose can mean the difference between continuous work and costly downtime. High-quality hoses designed for heavy-duty applications are engineered to survive extreme conditions while maintaining system performance and safety. One such example is the YUE CAI Hose 258‑0817, which shows the principles of toughness, reliability, and long-term performance.

Why Construction Machinery Hoses Are Essential

Hydraulic systems are the lifeblood of modern construction machinery. These systems provide power to attachments, steering mechanisms, and other critical operations. The hoses in these systems function as flexible channels for hydraulic fluid, connecting pumps, cylinders, valves, and actuators. Unlike ordinary hoses, those used in construction machinery face demanding conditions that include high pressure, extreme temperatures, exposure to chemicals, mechanical vibration, and abrasive contact with debris.

When a hose fails on a job site, it can lead to serious consequences: machine downtime, project delays, safety hazards, and environmental spills. This makes it critical to invest in hoses that are specifically designed to withstand rugged environments and maintain hydraulic performance under all conditions.

Introducing Hose 258‑0817

The Hose 258‑0817 is designed as a reliable replacement part for construction machinery. Manufactured with high-quality materials and precise engineering, this hose is capable of handling the serious demands of heavy-duty hydraulic systems. It is suitable for use in a variety of machines, including excavators, wheel loaders, cranes, graders, and bulldozers.

This hose is available as a new part and can be ordered individually, allowing operators to replace a single component or stock multiple units for larger fleets. Its design focuses on durability, performance, and ease of installation, making sure that machinery remains operational with minimal disruption.

Performance Features of Heavy-Duty Hoses

Construction machinery hoses must deliver consistent performance under challenging conditions. The 258‑0817 model excels in several critical areas:

Pressure Resistance

Hydraulic systems operate under high pressures that can vary rapidly during machine operation. Hoses must resist bulging, cracking, or bursting under these conditions. The 258‑0817 hose is engineered to maintain its integrity even under intense pressure, providing reliable performance for tasks such as lifting, digging, and material handling.

Temperature Stability

Construction machinery generates a large amount of heat, and hoses are often exposed to extreme environmental temperatures. A high-quality hose must resist softening in heat, remain flexible in cold conditions, and withstand repeated thermal cycling. The 258‑0817 hose offers excellent thermal stability, protecting both the hose itself and the hydraulic system it serves.

Abrasion and Chemical Resistance

Hoses are often exposed to mud, gravel, sharp edges, and other abrasive elements on a job site. They may also come into contact with hydraulic oils, lubricants, and other chemicals that can degrade inferior materials. The 258‑0817 hose is designed with abrasion-resistant outer layers and chemical-resistant compounds to ensure longevity and leak-free operation.

Versatility Across Machinery

One of the key advantages of the 258‑0817 hose is its versatility. It is compatible with a wide range of construction equipment, including excavators for digging and demolition, wheel loaders for material handling, cranes for lifting, and graders or bulldozers for precise earthmoving operations. This compatibility allows fleet managers to simplify spare parts inventory, reduce operational complexity, and respond quickly to hose failures without long downtime.

Quality and Reliability

High-quality hoses are essential for maintaining the reliability and safety of construction machinery. The 258‑0817 hose is manufactured with consistent quality standards, ensuring compatibility with both aftermarket and original equipment hydraulic systems. Reliable supply and consistent performance allow operators to minimize unexpected downtime, protect their machinery, and reduce maintenance costs.

Installation and Maintenance Tips

Proper installation and maintenance are critical to maximizing the life of construction machinery hoses. Key best practices include:

- Correct Fitment: Always ensure the hose matches the machine specifications.

- Clean Connections: Dirt or debris in fittings can lead to contamination and system failure.

- Torque Settings: Use manufacturer-recommended torque when securing fittings.

- Regular Inspections: Check for wear, cracks, and abrasions, and replace hoses proactively.

- Protective Routing: Avoid sharp edges, high heat areas, and contact with moving parts.

Following these practices will ensure the hose provides reliable service, prevents hydraulic leaks, and improves overall machine uptime.

The Importance of Investing in Quality Hoses

While hoses may seem like minor components in large machinery, they are the arteries of hydraulic systems. Using high-quality hoses like the 258‑0817 can impact:

- Machine uptime and productivity

- Operational safety and accident prevention

- Maintenance efficiency and cost reduction

- Overall hydraulic system performance

Neglecting hose quality may lead to failures, unexpected repairs, and costly delays, all of which negatively affect project outcomes and profitability.

Conclusion: Built for the Toughest Jobs

Construction machinery operates in some of the harshest environments imaginable. Hoses must withstand pressure, temperature extremes, abrasion, and chemical exposure while maintaining hydraulic performance. The YUE CAI 258‑0817 hose is built to meet these challenges, offering durability, reliability, and consistent performance for a wide range of machinery applications.

By choosing high-quality hoses and implementing proper installation and maintenance practices, operators can reduce downtime, protect their equipment, and keep projects on schedule. In the field of heavy construction, investing in durable hoses is smart — it is essential for success.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY