Optimize Excavator Output with a Durable and Intelligent Engine Controller System

- Karl

- 2025-12-01

- 68

The Central Role of the Engine Controller in Modern Excavators

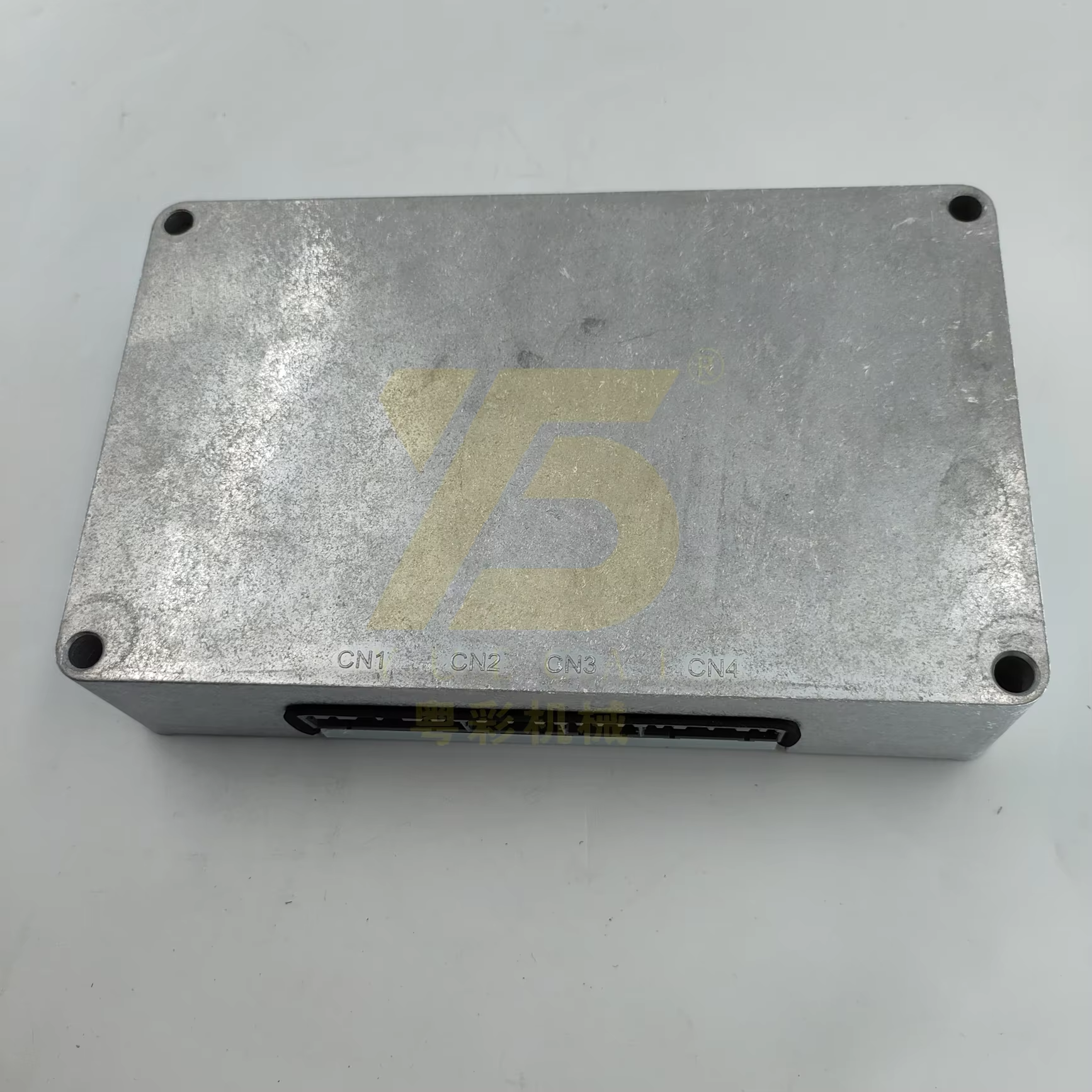

Excavators today operate in highly demanding environments where precision, power stability, and fuel efficiency define overall productivity. At the core of these expectations lies the engine controller, a component that acts as the machine’s brain. A durable and intelligent engine controller system continuously monitors load, fuel injection timing, airflow, and engine temperature, then adjusts power output to maintain optimal balance. This constant regulation allows the excavator to perform smoothly even under heavy workloads, preventing inconsistent power delivery and ensuring reliable operator control.

Durability That Withstands Harsh Operating Conditions

Engine controllers must function flawlessly in environments filled with heat, vibration, dust, moisture, and sudden workload shifts. Catvolvo's well-engineered, durable controller is designed with reinforced electronic architecture, sealed connectors, moisture-resistant housings, and anti-interference circuitry. These protective features guard against shock, corrosion, and electrical failure, ensuring the controller remains stable throughout long hours of excavation, lifting, trenching, or demolition. When a controller is built to withstand harsh conditions, downtime decreases, maintenance frequency drops, and overall operational reliability increases significantly.

Intelligent Control for Greater Power and Fuel Efficiency

An intelligent excavator engine controller transforms raw engine power into smooth, precise output. Using smart algorithms, it fine-tunes fuel injection, adjusts air intake, coordinates with hydraulic feedback, and regulates torque distribution in real time. This enables the excavator to accelerate smoothly, deliver powerful digging force, and operate with improved fuel economy. Intelligent controllers often include multiple operating modes—such as economy mode or heavy-power mode—allowing operators to match performance to specific tasks. This flexibility supports consistent output while avoiding unnecessary fuel consumption or machine strain.

Enhanced Diagnostics and Real-Time System Monitoring

A major advantage of modern engine controllers is their diagnostic intelligence. Integrated sensors provide continuous data on temperature, fuel pressure, combustion quality, and load conditions. If the controller detects abnormalities, it triggers warnings before the issue becomes critical. This early detection helps prevent severe engine damage, simplifies troubleshooting, and allows technicians to resolve problems quickly. The ability to store and analyze data also supports predictive maintenance strategies, reducing long-term costs and improving fleet management efficiency. Some advanced systems even support remote updates and monitoring, extending compatibility and system longevity.

Fuel Savings That Translate Into Long-Term Profitability

Fuel efficiency is one of the most tangible benefits provided by a high-quality engine controller. By regulating combustion timing, limiting unnecessary idling, and adjusting output based on workload, the controller significantly reduces fuel consumption. In long-hour construction projects, where excavators operate daily under varying load conditions, even small improvements in fuel burn rate create substantial long-term savings. Reduced fuel usage not only lowers operational costs but also decreases carbon emissions, helping companies meet environmental and regulatory requirements while maintaining competitive performance.

Smoother Operation and Higher Operator Confidence

A responsive excavator contributes to safety, comfort, and operational accuracy. An intelligent controller ensures that hydraulic response and engine behavior remain synchronized, enabling operators to perform fine-grading work, trench cutting, and heavy digging with better control. Smooth transitions reduce operator fatigue, minimize sudden jerks or unstable movements, and promote consistent work quality. Even operators with less experience can handle the machine more confidently because the controller stabilizes performance and manages power distribution automatically.

Long-Term Protection for the Engine and Key Components

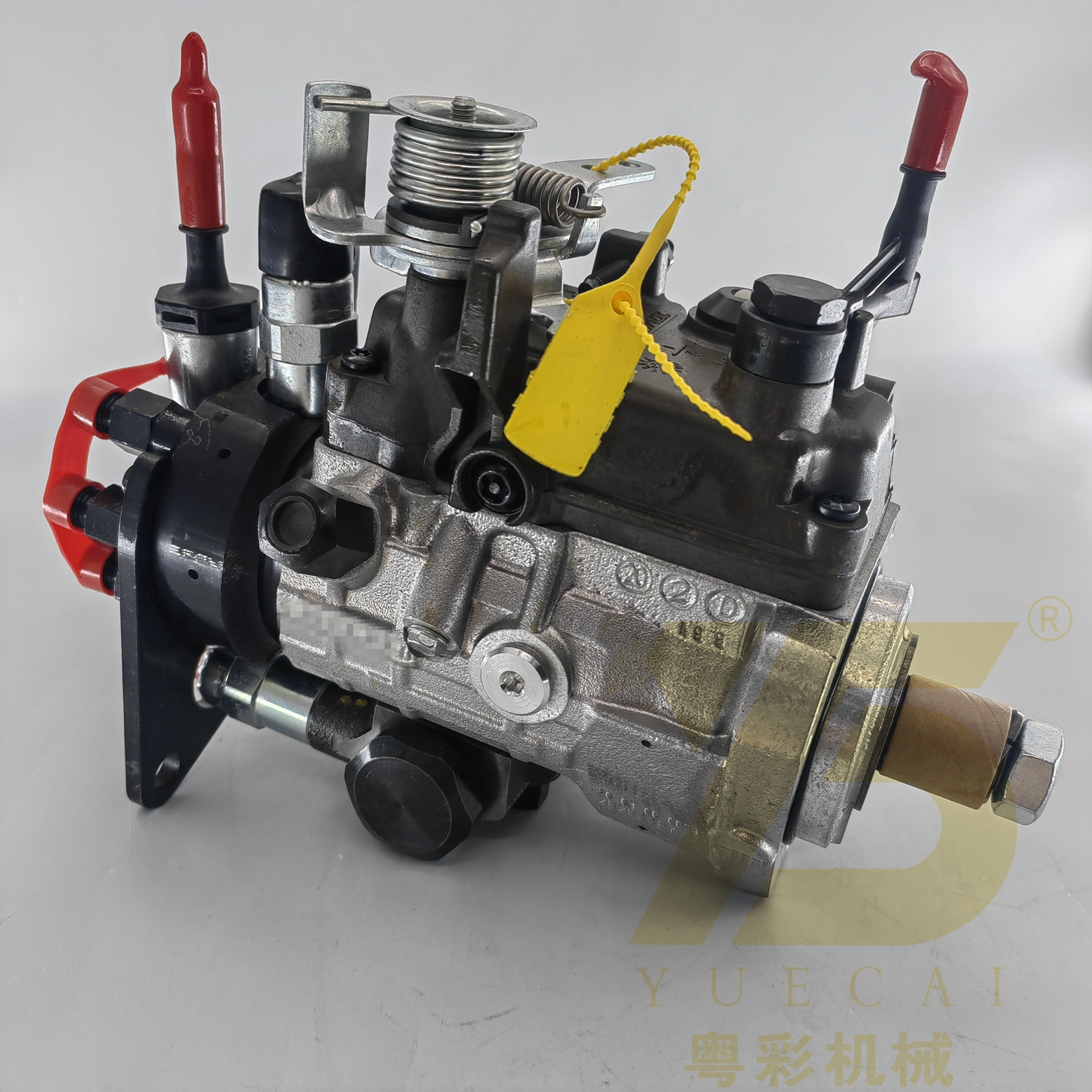

Beyond immediate performance enhancements, an advanced controller system promotes long-term engine health. By ensuring balanced combustion, preventing overload, and maintaining stable operating conditions, the system reduces wear on injectors, pistons, turbochargers, and fuel pumps. Lower stress on these components results in fewer failures, longer intervals between replacements, and a more stable service life for the excavator. For businesses investing heavily in equipment fleets, this long-term protection significantly improves asset value and reduces total ownership costs.

Why a Durable and Intelligent Controller Is the Key to Future-Ready Excavation

Investing in a high-quality engine controller is ultimately an investment in higher productivity, reduced downtime, and optimized resource use. As construction and mining operations move toward digital monitoring, sustainability goals, and precision-based performance standards, machines equipped with Catvolvo's advanced controller systems gain a clear advantage. A durable and intelligent engine controller ensures that the excavator delivers maximum output today while remaining fully capable of meeting tomorrow’s requirements in fuel regulation, emissions control, and operational data integration.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

-

Excavator Engine Controller ECU Boosts Performance Efficiency

Give Us What You Need

SUBSCRIBE

INQUIRY