Excavator Engine Controller ECU Boosts Performance Efficiency

- jumi

- 2025-12-05

- 55

In today’s construction and earthmoving industry, the excavator engine controller ECU has become the central component that determines how efficiently a machine can operate. As excavators transition toward smarter hydraulic systems and data-driven control logic, the stability and precision of the ECU directly influence fuel economy, engine responsiveness, and overall output. The controller continuously assesses load conditions, adjusts fuel injection timing, and regulates torque, allowing the machine to deliver consistent and predictable performance even under heavy or fluctuating workloads. For contractors and fleet owners, the ECU is not merely an electronic unit but the operational command center that governs real-world productivity.

Reliable ECU Models Supporting Stable Engine Output

Popular ECU models such as KHR10023, KHR10025, KHR10026, KHR10027, and KHR10028 are widely valued for their durability and compatibility across different excavator engines. These controllers integrate signals from multiple sensors—ranging from throttle position to crankshaft speed—to achieve a fine-tuned combustion balance. When calibrated correctly, they keep engine RPM stable, reduce vibration, and maintain power delivery even in environments involving dust, high temperatures, humidity, or long operational cycles. Machines equipped with these ECUs typically show smoother transitions between digging, traveling, and lifting operations, resulting in reduced operator fatigue and improved work efficiency.

Enhanced Control Response and Operational Efficiency

One of the clearest advantages of a high-quality ECU is its immediate response to operator input. Advanced algorithms interpret joystick movements and hydraulic pressure data simultaneously, sending micro-adjustments to the engine to ensure quick acceleration and controlled torque output. Excavators running KHR10026 or KHR10027 often demonstrate quicker cycle times due to this refined responsiveness. The ECU also plays a critical protective role by storing fault codes and triggering safety protocols when sensors detect abnormal temperature, load, or pressure. This reduces the likelihood of breakdowns, minimizes downtime, and helps extend the service life of core components.

Supporting Environmental Compliance and Diagnostic Accuracy

Modern ECUs contribute significantly to emissions management. Controllers like KHR10023 and KHR10028 stabilize combustion during heavy load changes, reducing black smoke and helping the machine meet increasingly strict environmental standards. They also support diagnostic tools that give mechanics and operators transparent insight into engine behavior. Rather than guessing whether a problem originates from sensor drift, fuel delivery, or wiring fatigue, technicians can review ECU feedback directly and resolve issues quickly, improving maintenance efficiency.

Advancing Toward Intelligent and Connected Excavation

As machinery grows more digital and automated, ECUs continue to evolve with stronger processors, better waterproof protection, and improved anti-vibration construction. Models including KHR10025 and KHR10026 now integrate smoothly with telematics systems, enabling remote monitoring, performance analysis, and preventive maintenance planning. This development supports safer operation and enhances confidence in long-term fleet management, giving excavation teams a clear operational advantage.

Delivering Reliable ECU Solutions for Global Excavators

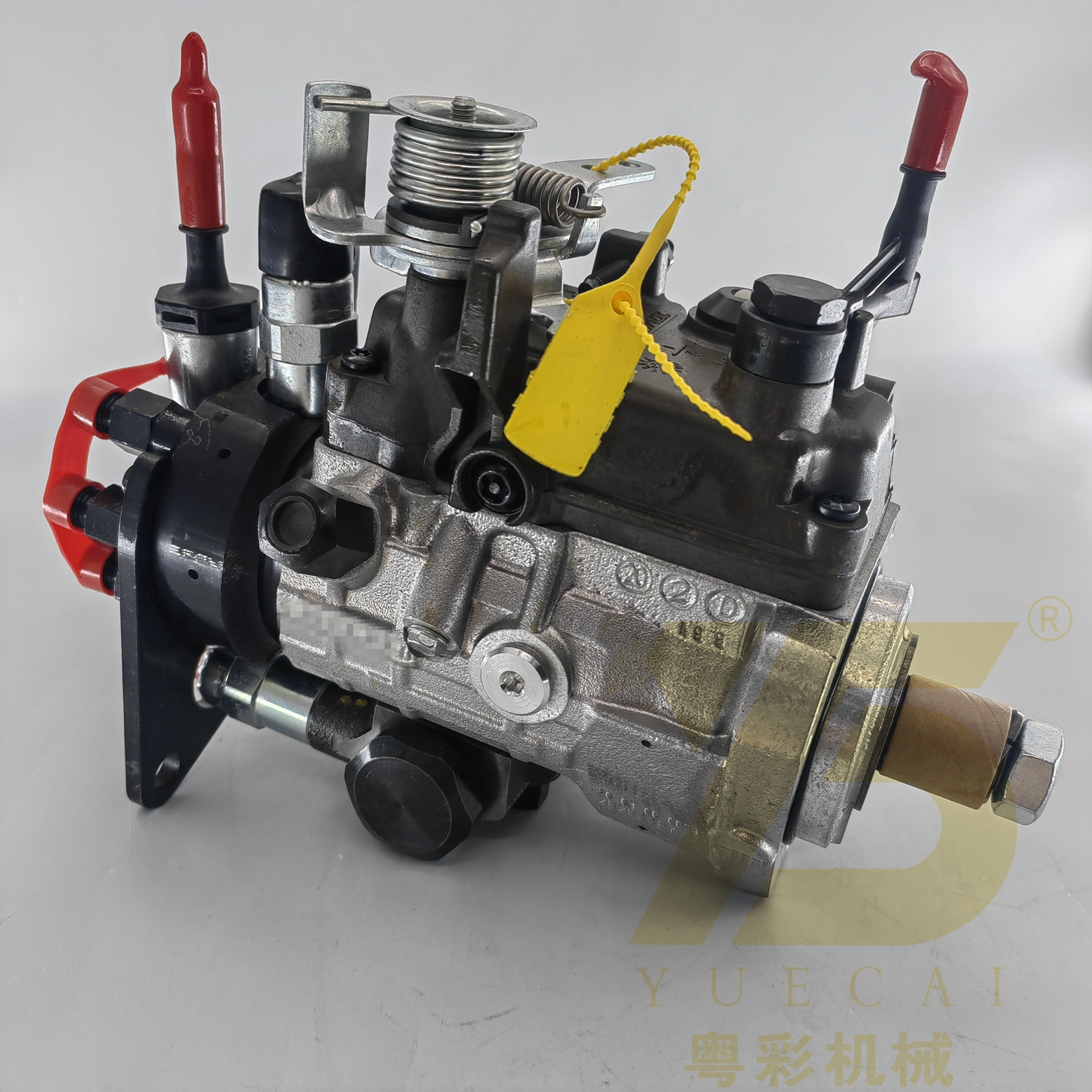

At the forefront of this technological progress, YUE CAI provides high-quality excavator engine controllers and professional support for clients worldwide. The brand is recognized for stable performance, precise engineering, and durable construction across ECU models such as KHR10023, KHR10025, KHR10026, KHR10027, and KHR10028. Whether customers are upgrading older machines or maintaining a modern fleet, YUE CAI offers dependable solutions backed by deep technical experience and a commitment to keeping equipment running at peak efficiency.

Conclusion: The ECU as the Brain of Excavator Efficiency

In a competitive construction environment, every minute of reliable performance matters. A well-engineered excavator engine controller ECU ensures optimized fuel usage, consistent power delivery, and long-term component stability. With the continuous development of intelligent control systems, high-quality ECUs—especially those from YUE CAI—will remain essential to achieving efficient, productive, and safe machinery performance. As the industry advances, YUE CAI will continue delivering the solutions that help machines perform at their best in demanding job-site conditions.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY