Engine Turbocharger Design for Reliability in Heavy Machinery

- jumi

- 2026-01-28

- 15

In heavy machinery applications, engine reliability is not a preference—it is a necessity. Equipment used in construction, mining, industrial power generation, and large-scale infrastructure projects operates under continuous load, harsh environments, and extended service cycles. Within these demanding conditions, the engine turbocharger plays a decisive role in determining overall engine efficiency, durability, and long-term operational stability.

A well-designed turbocharger enables a diesel engine to deliver higher power output without increasing engine size, while maintaining fuel efficiency and consistent performance. For heavy machinery engines, turbocharger reliability directly affects machine uptime, operating costs, and maintenance planning. This is why turbocharger design is a critical consideration when selecting components for industrial and off-road engines.

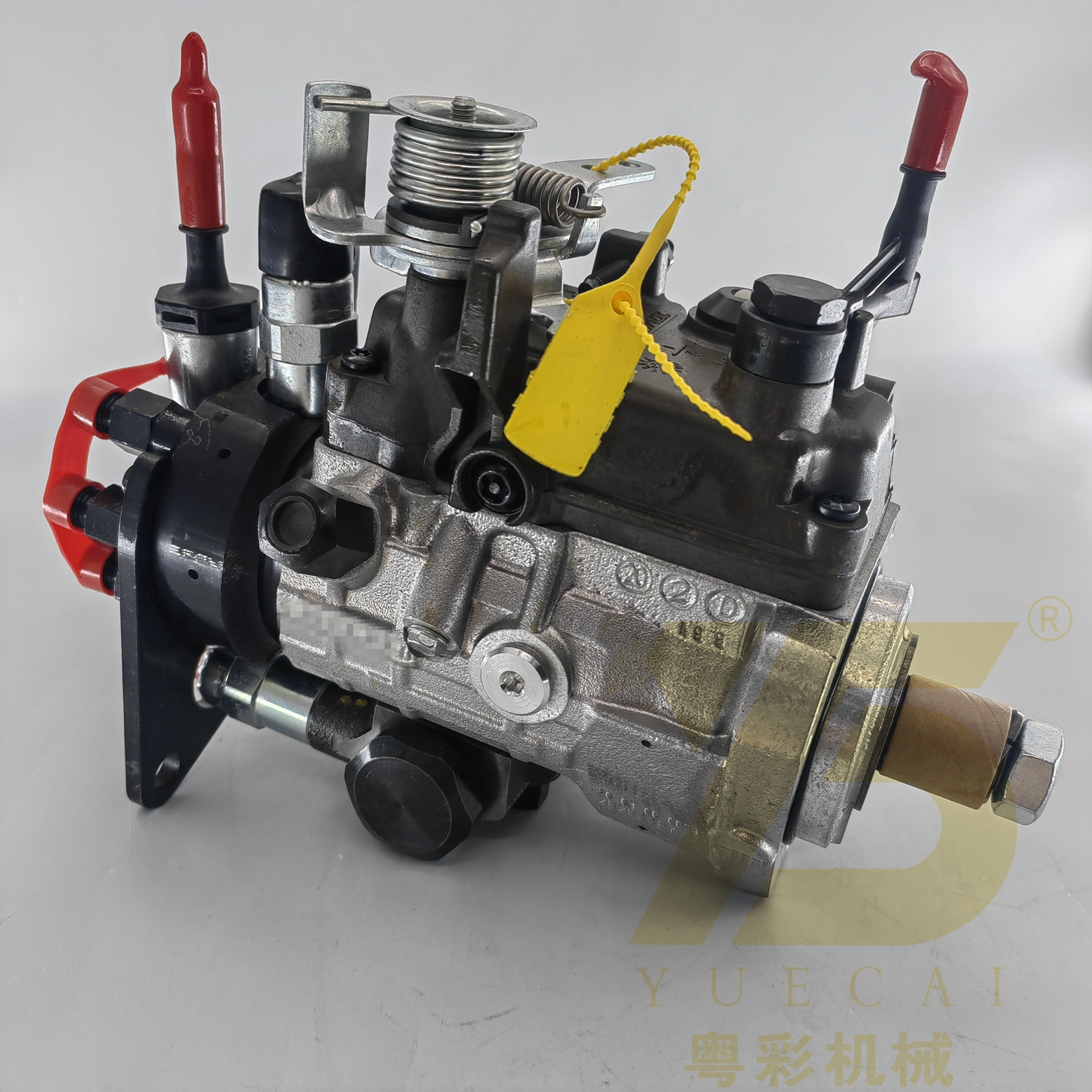

Using the YUE CAI Twin Turbocharger TAD1643 as a reference, this article explores how turbocharger design supports reliability in heavy machinery and why twin turbocharging systems are increasingly valued in high-load engine applications.

The Importance of Turbochargers in Heavy Machinery Engines

Turbochargers are essential components in modern heavy-duty diesel engines. By adopting exhaust gas energy to compress intake air, a turbocharger increases the amount of oxygen available for combustion. This process allows the engine to burn fuel more efficiently, resulting in higher torque output and improved fuel economy.

In heavy machinery, engines are expected to deliver stable power over long periods, often in environments with high temperatures, dust, vibration, and fluctuating load demands. Without a properly engineered turbocharger, engines would struggle to meet these requirements while maintaining acceptable fuel consumption and emissions levels.

The reliability of a turbocharger is therefore directly tied to the reliability of the entire machine. A failure in the turbocharging system can lead to power loss, increased fuel usage, unplanned downtime, and in severe cases, engine damage. For this reason, heavy machinery manufacturers and operators place strong emphasis on turbocharger design quality and component compatibility.

Understanding Twin Turbocharger Systems

A twin turbocharger system uses two turbocharger units working together to support a single engine. This configuration is especially beneficial for large-displacement diesel engines commonly used in heavy machinery. Rather than relying on a single large turbocharger, a twin turbo setup distributes airflow and exhaust energy across two units.

The YUE CAI Twin Turbocharger TAD1643 is designed specifically for heavy-duty engine applications where consistent airflow, balanced boost pressure, and long-term durability are required. By splitting the workload between two turbochargers, the system helps improve engine responsiveness and maintain stable performance across different operating conditions.

Twin turbocharging is not only about increasing power. In heavy machinery, it is equally about improving reliability by reducing stress on individual components. When exhaust pressure and thermal loads are shared, each turbocharger operates within a more controlled range, which supports longer service life and reduced wear.

How Turbocharger Design Impacts Reliability

Turbocharger reliability is determined by a combination of engineering decisions, material selection, manufacturing precision, and compatibility with the engine platform. In heavy machinery applications, these factors become even more critical due to extended operating hours and harsh working environments.

Structural Strength and Durability

Heavy machinery turbochargers must withstand extreme exhaust temperatures and high rotational speeds. The turbine and compressor housings are exposed to continuous thermal cycling, while internal rotating components operate at very high RPM levels. A reliable turbocharger design requires sturdy construction that can maintain structural integrity under these conditions.

The YUE CAI Twin Turbocharger TAD1643 is positioned as a new, heavy machinery–grade component, intended for engines that demand durability and consistent output. This indicates a design approach focused on strength, resistance to deformation, and suitability for long-term industrial use.

Balanced Performance Across Operating Conditions

Heavy machinery engines rarely operate at a single, steady speed. Load conditions change frequently depending on the task, terrain, and equipment usage. A turbocharger must respond smoothly to these changes without creating excessive lag or instability in airflow.

Twin turbocharger systems are particularly effective in managing varying operating conditions. By providing consistent boost pressure across a wider RPM range, the engine can maintain smooth torque delivery and reduce sudden stress spikes. This balanced performance contributes directly to engine reliability and operator confidence.

Precision Assembly and Component Matching

Reliability in turbocharger systems is also influenced by how precisely components are assembled and matched. Poor alignment or imbalance can lead to vibration, accelerated bearing wear, and reduced efficiency. For twin turbo systems, precise matching between the two turbochargers is especially important to ensure synchronized operation.

Turbochargers designed for specific engine models—identified by exact part numbers such as 3774247 and 3819093—help ensure correct fitment and optimal performance. Proper component matching reduces installation errors and minimizes the risk of premature failure.

Supporting Long-Term Engine Performance

Turbocharger reliability extends beyond initial performance. In heavy machinery, engines are expected to operate reliably over thousands of hours. A well-designed turbocharger supports this goal by maintaining stable airflow, reducing combustion inefficiencies, and minimizing thermal stress on engine components.

Twin turbocharging helps engines achieve higher power density without overloading individual parts. This approach supports smoother combustion, more consistent exhaust temperatures, and improved overall engine balance. Over time, these factors contribute to reduced maintenance requirements and extended engine service intervals.

Practical Benefits for Heavy Machinery Operators

From the operator’s perspective, turbocharger reliability translates directly into operational efficiency. Equipment that maintains consistent power output allows operators to complete tasks more quickly and predictably. Reduced downtime means fewer interruptions and lower repair costs.

The availability of new, aftermarket turbochargers such as the YUE CAI Twin Turbocharger TAD1643 also plays a role in fleet management. Having access to compatible replacement parts supports faster repairs and minimizes the impact of unexpected component wear or failure.

Installation and Compatibility Considerations

In heavy machinery maintenance, ease of installation is an important factor. Turbochargers designed with standard mounting interfaces and clearly defined part numbers simplify the replacement process. Proper fitment reduces the risk of installation-related issues and ensures that the turbocharger performs as intended.

A twin turbocharger system must integrate perfectly with the engine’s intake, exhaust, and lubrication systems. When compatibility is properly addressed at the design stage, the result is a turbocharger that supports reliable engine operation without requiring extensive modifications.

Warranty and Product Confidence

Reliability is also reflected in the support provided with the product. A defined warranty period demonstrates confidence in manufacturing quality and material durability. For heavy machinery components, even a limited warranty offers reassurance to operators and maintenance teams, especially during initial installation and commissioning.

The inclusion of a warranty reinforces the expectation that the turbocharger is suitable for demanding industrial use and capable of meeting performance requirements under real-world conditions.

Conclusion: Reliability Starts with Turbocharger Design

In heavy machinery applications, turbocharger design plays a critical role in ensuring engine reliability, efficiency, and long-term performance. From structural durability and balanced airflow to precise component matching and compatibility, every design choice contributes to how well a turbocharger performs under load.

The YUE CAI Twin Turbocharger TAD1643 represents a turbocharging solution designed for heavy-duty engines that require stable output and dependable operation. By adopting a twin turbo configuration and focusing on industrial-grade performance, this type of turbocharger supports the needs of modern heavy machinery across construction, industrial, and power generation applications.

Investing in well-designed turbocharger systems helps equipment owners reduce downtime, extend engine life, and maintain productivity in the most demanding working environments. When reliability is a priority, turbocharger design is a factor that cannot be overlooked.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY