Essential Guide to Oil Filter for Excavator Applications

- jumi

- 2026-01-17

- 30

Excavators operate under some of the most demanding conditions in the construction, mining, and infrastructure industries. Continuous exposure to dust, heavy loads, high temperatures, and long working hours places extreme stress on engine systems. Among all engine components, the oil filter plays a fundamental role in maintaining engine reliability and long-term performance. This essential guide explores the function of oil filters in excavator applications, key selection criteria, and the practical advantages of using a purpose-built oil filter such as the YUE CAI Oil Filter for modern excavator engines.

The Importance of Oil Filtration in Excavator Engines

An excavator engine relies on clean, properly lubricated oil to function efficiently. During operation, engine oil circulates through multiple moving components, collecting contaminants such as dust particles, metal shavings, carbon residues, and combustion by-products. Without effective filtration, these impurities can cause accelerated wear, overheating, and mechanical failure.

The oil filter acts as a protective barrier between contaminants and critical engine components. By removing harmful particles from the oil before it recirculates, the filter ensures smoother operation, reduced friction, and stable oil pressure. For excavators that often work in harsh environments, oil filtration is not simply a maintenance task—it is a core requirement for equipment longevity and operational safety.

How Oil Filters Support Excavator Performance and Longevity

Oil filters are designed to support excavator engines in several key ways. First, they help maintain consistent oil cleanliness, which directly affects engine efficiency. Clean oil flows more freely and lubricates components more effectively, reducing resistance and heat generation.

Second, oil filters help extend engine service life. When abrasive contaminants are removed from the lubrication system, internal engine parts such as pistons, crankshafts, bearings, and camshafts experience less wear. This translates into longer intervals between major repairs and lower total cost of ownership.

Finally, reliable oil filtration reduces the risk of unexpected downtime. Excavators are often deployed on time-sensitive projects, and engine failures can lead to costly delays. A dependable oil filter minimizes the risk of oil-related engine damage, allowing equipment to operate consistently under heavy workloads.

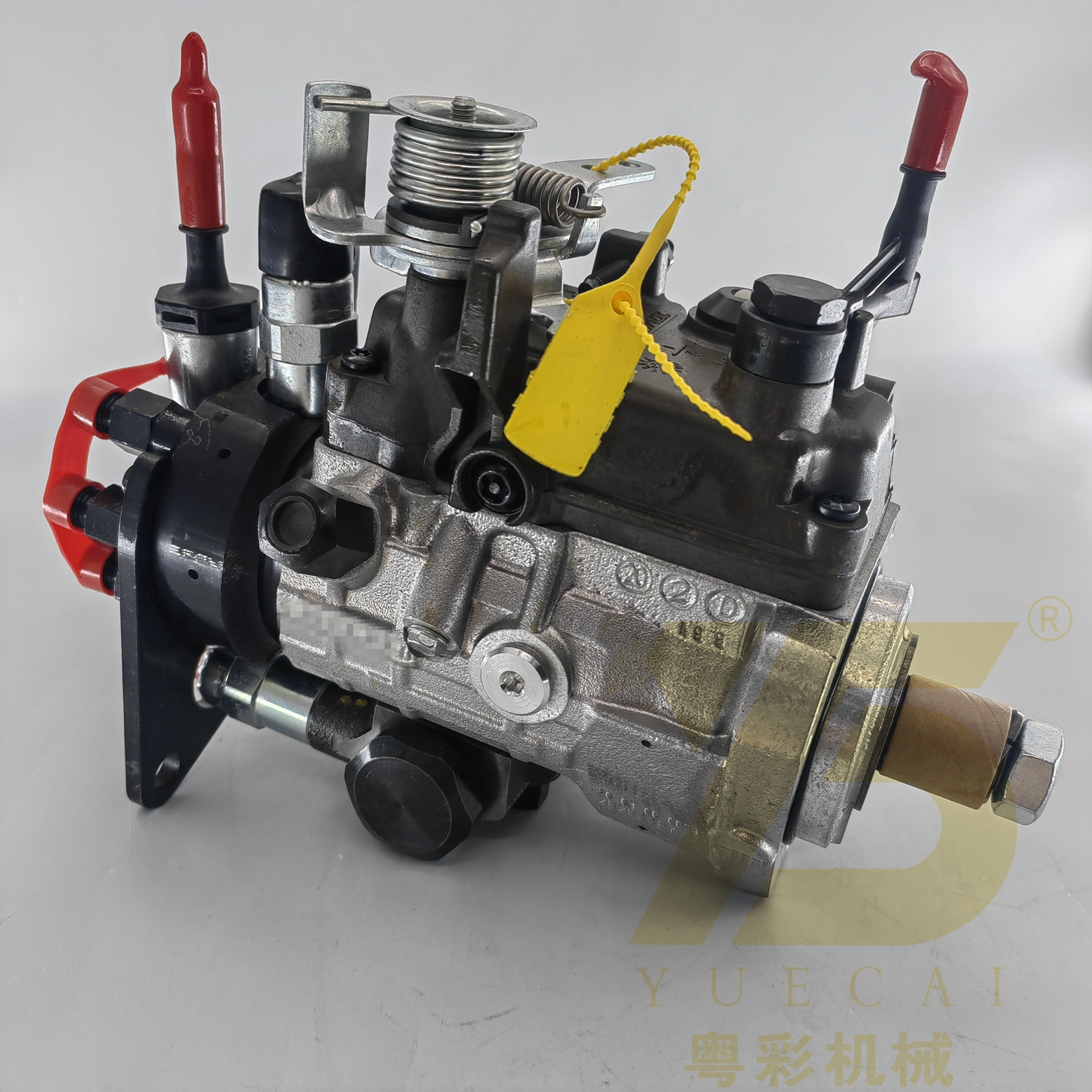

Overview of the YUE CAI Oil Filter for Excavator Applications

The YUE CAI Oil Filter is designed specifically for use in excavator engines and machinery spare parts applications. It is a new-condition product manufactured in Guangdong, China, and supplied under the YUE CAI brand. This oil filter is compatible with multiple excavator models, including commonly used machines such as the 313GC, 315GC, and 317GC.

One of the notable advantages of this oil filter is its availability. The product is maintained in stable stock, allowing customers to source replacement filters quickly without extended lead times. This is particularly important for maintenance teams and distributors that need to support ongoing machine operation.

The oil filter is offered with a three-month warranty, reflecting standard industry practices for consumable engine components. Its low minimum order quantity also makes it suitable for both individual equipment owners and larger fleet operators.

Key Functional Characteristics of the YUE CAI Oil Filter

The YUE CAI Oil Filter is engineered to meet the filtration demands of excavator engines operating under heavy load conditions. Its internal filtration structure is designed to capture fine particles that circulate within engine oil during normal operation. By effectively trapping these contaminants, the filter helps maintain stable oil viscosity and pressure.

Another important characteristic is structural reliability. Oil filters must withstand continuous oil flow, pressure fluctuations, and temperature changes. A stable filter housing and sealing structure help prevent oil leakage and ensure consistent performance throughout the service interval.

Compatibility is also a critical factor. Using an oil filter that matches the correct specifications and part references ensures proper installation and optimal filtration performance. The YUE CAI oil filter corresponds to multiple reference numbers, making it suitable for replacement and maintenance needs across compatible excavator models.

Choosing the Right Oil Filter for Excavator Maintenance

Selecting the correct oil filter is essential for effective excavator maintenance. One of the first considerations should always be part number compatibility. An oil filter must match the engine’s design parameters to ensure correct fitment, sealing, and oil flow characteristics.

Operating conditions should also influence filter selection. Excavators working in dusty or high-load environments may require more frequent oil and filter changes. In such cases, choosing a filter designed specifically for excavator applications helps maintain consistent filtration efficiency throughout the operating cycle.

Availability and logistics are equally important. Filters that are consistently in stock reduce downtime and simplify maintenance planning. For contractors and fleet operators, the ability to quickly replace oil filters can have a direct impact on project schedules and productivity.

Best Practices for Installing Excavator Oil Filters

Even the best oil filter cannot perform effectively if it is installed incorrectly. Proper installation begins with inspecting the new filter for visible damage and making sure that the sealing surface is clean. Any debris on the mounting surface can compromise the seal and lead to oil leakage.

Applying a light layer of clean engine oil to the filter gasket before installation helps ensure a secure seal and makes future removal easier. The filter should be tightened according to recommended specifications, as over-tightening can damage the filter housing, while under-tightening may cause leaks.

After installation, it is recommended to run the engine briefly and check for leaks. Monitoring oil pressure and engine behavior during the initial operating period helps confirm that the filter is functioning correctly.

The Role of Reliable Suppliers in Excavator Parts Sourcing

Sourcing oil filters from specialized construction machinery parts suppliers offers distinct advantages. Suppliers with a focused product range and technical expertise can provide components that meet the specific needs of excavator engines. This reduces the risk of compatibility issues and improves overall maintenance efficiency.

Companies specializing in excavator parts typically maintain inventory across a wide range of engine components, including oil filters, pumps, controllers, and electrical systems. This integrated approach allows customers to source multiple parts from a single supplier, simplifying procurement and logistics.

Consistent product availability, technical support, and industry experience are all factors that contribute to long-term reliability when sourcing oil filters and other engine components.

Conclusion

Oil filters are a critical component in excavator engine systems, directly affecting performance, reliability, and service life. In demanding work environments, effective oil filtration helps protect internal engine components, reduce wear, and prevent costly downtime.

The YUE CAI Oil Filter offers a practical solution for excavator maintenance, with compatibility across multiple excavator models, stable stock availability, and a design suited for heavy-duty machinery applications. By understanding the role of oil filters and following best practices for selection and installation, equipment operators can greatly improve engine durability and operational efficiency. Regular maintenance, combined with the application of reliable oil filters, remains one of the most effective ways to make excavators continue to perform efficiently throughout their service life.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY