In modern construction and earthmoving projects, excavators are expected to deliver consistent power, fuel efficiency, and long-term reliability under demanding conditions. Behind this performance is a complex diesel engine system, where fuel delivery plays a decisive role. One of the most critical components in this system is the engine common rail injector. For excavators such as the Volvo EC210 and EC210B series, the YUE CAI 0445120067 Common Rail Injector is designed to support stable engine operation, precise fuel control, and efficient combustion. Understanding how this injector works and how it improves engine performance can help equipment owners and fleet managers make smart decisions when maintaining or upgrading their machines.

The Role of a Common Rail Injector in Excavator Engines

A common rail injector is a precision component used in modern diesel engines to deliver fuel into the combustion chamber at extremely high pressure. Unlike older mechanical injection systems, a common rail system allows fuel pressure to remain constant while injection timing and fuel quantity are electronically controlled. This design enables the injector to respond accurately to different engine loads and operating conditions. In excavator engines, where workloads change frequently, this level of control is essential. The YUE CAI 0445120067 injector is engineered to meet these demands by ensuring stable and accurate fuel injection throughout the engine’s operating range.

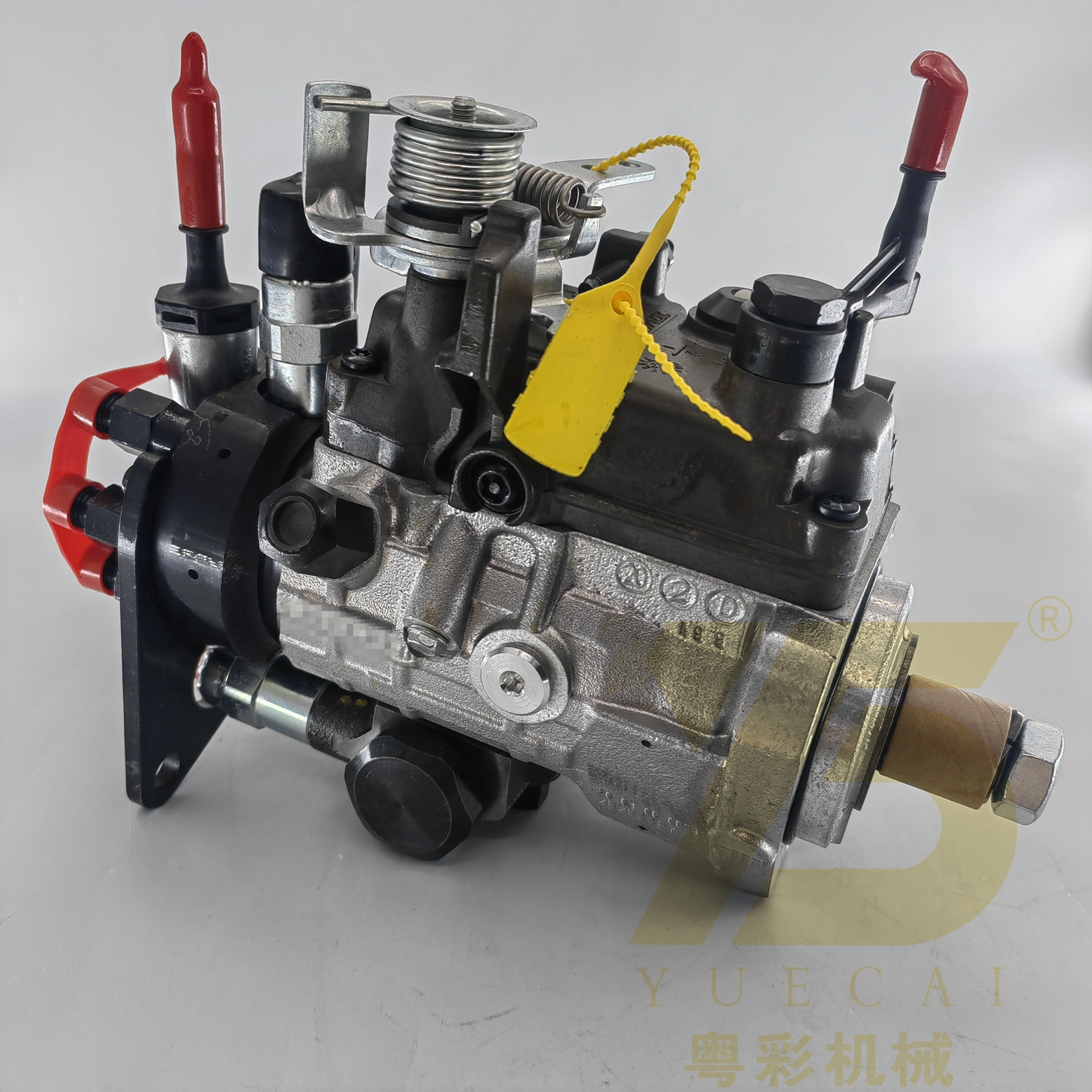

Overview of the YUE CAI 0445120067 Common Rail Injector

The YUE CAI 0445120067 is a new engine common rail injector developed for excavator applications. It is commonly used as a replacement part for excavator engines that require reliable fuel injection performance. Key product characteristics include its compatibility with specific excavator engine models, precision manufacturing standards, and a design that supports consistent fuel delivery. With a single-piece minimum order quantity and a defined warranty period, it is suitable for both individual repairs and fleet maintenance needs.

How Precise Fuel Injection Improves Combustion Efficiency

One of the most remarkable advantages of a high-quality common rail injector is improved combustion efficiency. Combustion efficiency refers to how completely the fuel is burned inside the engine cylinder. The injector delivers fuel at controlled pressure and timing, allowing the diesel fuel to atomize into fine droplets. Finer atomization increases the contact area between fuel and air, enabling more complete combustion. As a result, more energy is extracted from the same amount of fuel, directly improving engine output. Better combustion also reduces unburned fuel residue, which helps keep internal engine components cleaner over time.

Enhanced Power Output and Engine Responsiveness

Excavators must perform heavy digging, lifting, and traveling tasks that demand stable torque and fast response. Engine responsiveness depends largely on how quickly and accurately fuel is delivered during combustion. With a common rail system, the injector can perform multiple injections during a single combustion cycle if required. This allows smoother power delivery and more controlled pressure buildup inside the cylinder. The injector supports this process by maintaining consistent injection performance, even under sudden load changes. Operators benefit from smoother acceleration, improved low-speed torque, and more predictable engine behavior during demanding operations.

Fuel Efficiency and Reduced Operating Costs

Fuel consumption is one of the largest ongoing expenses in excavator operation. Even small improvements in fuel efficiency can result in substantial cost savings over time. Because the injector precisely meters fuel according to engine demand, it minimizes fuel waste caused by over-injection or incomplete combustion. When the engine receives only the fuel it needs, fuel efficiency improves without compromising performance. Improved fuel efficiency also means fewer refueling interruptions, helping operators maintain productivity during long working hours.

Cleaner Engine Operation and Lower Emissions

Modern construction equipment is increasingly required to meet stricter environmental standards. Emissions are directly influenced by fuel combustion quality. Accurate fuel injection reduces the formation of soot and particulate matter. When fuel burns more completely, fewer harmful byproducts are released through the exhaust. The injector supports cleaner combustion by ensuring stable injection timing and consistent spray patterns. Cleaner combustion not only helps meet environmental expectations but also reduces carbon buildup inside the engine, which can extend service intervals and improve long-term reliability.

Durability Designed for Heavy-Duty Excavator Use

Excavator engines operate in harsh environments, often exposed to dust, vibration, high temperatures, and continuous load cycles. Components within the fuel system must be designed to withstand these conditions. The common rail injector is manufactured with durability in mind. Its construction supports long-term operation under high pressure and temperature, helping maintain stable performance throughout its service life. A durable injector reduces the likelihood of unexpected engine issues, contributing to higher machine uptime and lower maintenance costs.

Reliable Performance for Excavator Engine Stability

Engine stability is essential for both performance and safety. Inconsistent fuel injection can lead to rough idling, power loss, or increased engine wear. By maintaining accurate fuel delivery across different operating conditions, the injector helps stabilize engine speed and combustion behavior. This stability improves overall engine smoothness and reduces mechanical stress on pistons, valves, and other internal components. Stable engine performance also improves operator comfort and control, especially during precision tasks.

Ease of Replacement and Maintenance Compatibility

For maintenance professionals, ease of installation is an important consideration. A well-designed injector should integrate perfectly into the existing fuel system without requiring complex adjustments. The injector is designed as a direct-fit replacement for compatible excavator engines. This simplifies the replacement process, reduces labor time, and allows machines to return to operation quickly. When combined with proper fuel system maintenance practices, such as clean fuel supply and regular filter replacement, the injector can deliver reliable performance throughout its service period.

Why Choosing the Right Common Rail Injector Matters

Not all injectors deliver the same level of performance. Using a correctly specified injector that meets engine requirements is essential for maintaining optimal performance. The common rail injector is developed for excavator engine applications where power, efficiency, and durability are critical. Choosing a suitable injector helps protect the engine from performance loss, excessive fuel consumption, and premature wear. For equipment owners, this means better return on investment and reduced long-term operating risk.

Conclusion

A common rail injector plays a critical role in determining how well an excavator engine performs. From fuel efficiency and power output to emissions control and engine durability, its impact is far-reaching. The common rail injector supports improved excavator engine performance through precise fuel delivery, efficient combustion, and reliable operation under demanding conditions. Maintaining stable engine behavior and reducing fuel waste contribute to lower operating costs and extended engine life. For excavator operators and maintenance teams, investing in the right common rail injector is not only about replacement — it is about ensuring consistent performance, productivity, and reliability in every working hour.