Prevent Industrial Engine Failure with a Reliable Oil Sensor

- jumi

- 2026-01-30

- 27

Keeping industrial engines running at peak performance is critical for sectors such as construction, mining, logistics, and heavy manufacturing. Among the many components that ensure reliable engine operation, the engine oil sensor is often overlooked. Yet, it is one of the most critical parts for maintaining engine health, preventing unexpected failures, and reducing maintenance costs. A reliable oil sensor provides accurate monitoring of lubrication systems, enabling operators to address issues before they escalate into expensive downtime.

The Role of Oil Sensors in Industrial Engines

Industrial engines rely heavily on proper lubrication to function efficiently under extreme conditions, including high temperatures, heavy loads, and constant vibration. Engine oil reduces friction between moving parts, carries heat away from components, and prevents corrosion. When oil pressure drops or becomes inconsistent due to leaks, contamination, or excessive consumption, engine components are at risk of accelerated wear or sudden failure.

An engine oil sensor monitors real-time oil pressure, and in some cases oil level and temperature, relaying critical information to the engine control system. This feedback allows the engine management unit to take corrective actions such as triggering alerts, reducing engine load, or initiating emergency shutdowns. By detecting issues early, oil sensors protect engines from catastrophic damage and extend the equipment’s operational life.

Why Reliable Oil Sensors Are Essential for Heavy Machinery

Early Detection of Lubrication Problems

Without proper monitoring, low oil pressure can go unnoticed until symptoms like abnormal noises, overheating, or excessive wear become evident. High-quality oil sensors detect these problems early, giving maintenance teams the opportunity to address them before they result in major failures. Early detection not only preserves engine components but also helps maintain continuous productivity.

Minimizing Unplanned Downtime

For operators of excavators, wheel loaders, bulldozers, or industrial generators, even a few hours of unplanned downtime can lead to project delays and massive financial losses. Reliable oil sensors help prevent unexpected stoppages by alerting operators and maintenance teams as soon as abnormal pressure levels are detected. This allows corrective actions to be taken before operations are disrupted.

Extending Engine Lifespan

Maintaining proper lubrication reduces wear on internal engine components such as bearings, seals, and pistons. A dependable oil sensor ensures consistent oil pressure, preventing heat-related damage and premature engine failure. Over time, this translates into lower maintenance costs and a longer total lifespan for heavy machinery.

Features of a High-Performance Engine Oil Sensor

High-performance engine oil sensors are designed to provide precise pressure readings and reliable performance in demanding work environments. Key characteristics include:

- Accurate Pressure Monitoring: High-quality sensors provide real-time data on oil pressure, enabling prompt detection of anomalies.

- Durable Construction: Industrial-grade sensors are built to withstand heat, vibration, and harsh operating conditions.

- OEM-Level Compatibility: Sensors are engineered to match original equipment specifications, ensuring proper fit and accurate readings.

- Ease of Installation and Maintenance: Designed for straightforward integration and minimal downtime during replacement.

By choosing a sensor with these features, operators can ensure that their engines receive reliable monitoring and protection, even under heavy workloads.

Integration with Engine Control Systems

Modern industrial engines often rely on sophisticated engine control units that monitor multiple parameters in real time. Oil sensors play a critical role in this system by providing continuous feedback on oil pressure. The engine control unit evaluates this data and can respond in several ways when abnormal conditions are detected:

- Triggering visual or audible alerts for operators

- Reducing engine power to protect internal components

- Initiating controlled shutdowns to prevent catastrophic damage

This integration ensures that engines operate safely and efficiently while minimizing the risk of costly failures.

Choosing the Right Oil Sensor Supplier

When sourcing replacement parts for industrial engines, the choice of supplier is as important as the part itself. Reliable suppliers maintain high standards of quality, provide OEM-level or compatible parts, and ensure timely delivery to minimize downtime. Businesses that invest in trusted suppliers benefit from consistent product quality, technical support, and access to a broad range of parts suitable for various engine models.

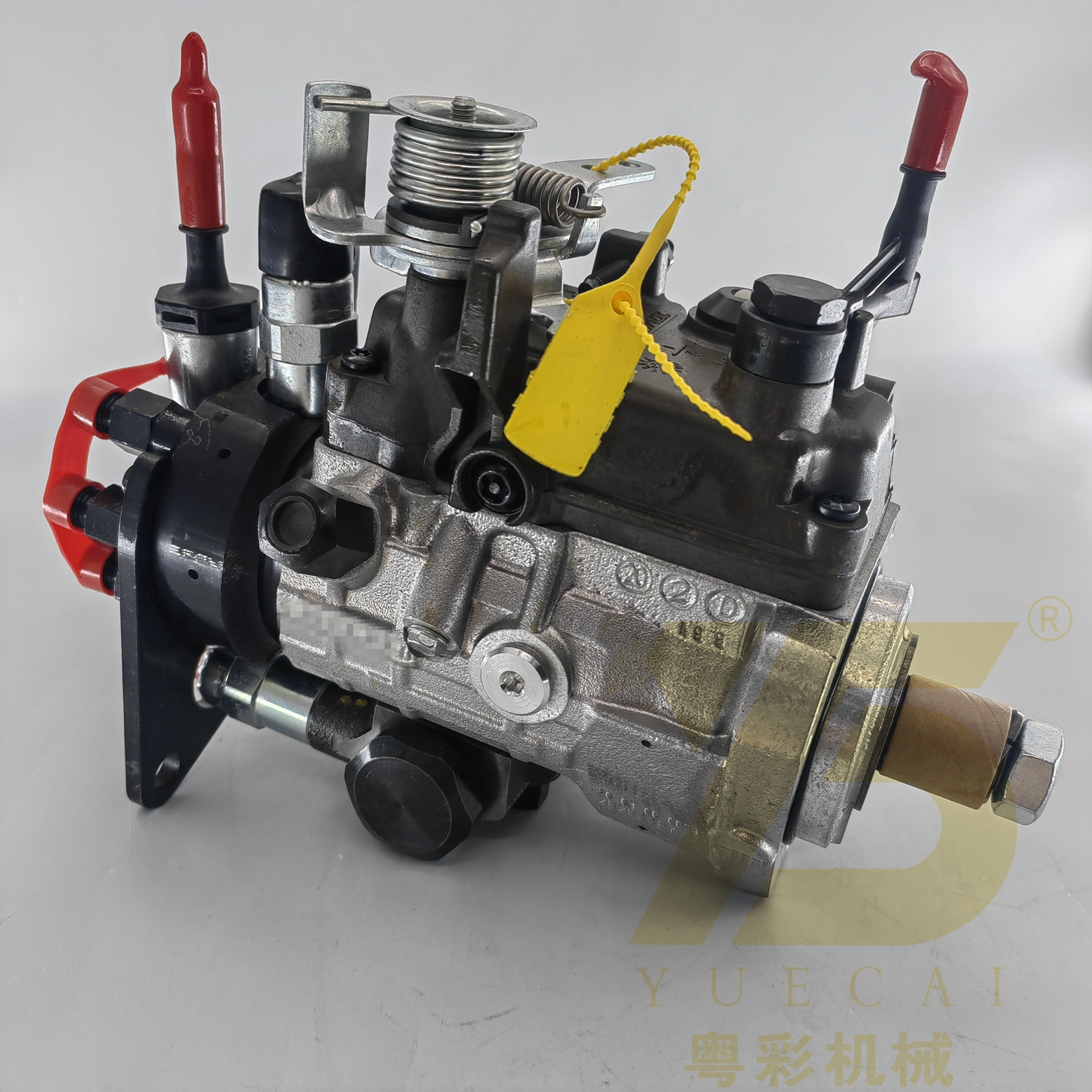

Selecting the right oil sensor from a reputable supplier, such as Yue Cai, ensures that engines receive accurate pressure readings, maintenance planning is optimized, and operational reliability is maximized. A high-quality sensor is more than a replacement part—it is an essential component in safeguarding the engine’s performance and the company’s bottom line.

Best Practices for Maintaining Oil Sensors

To maximize the lifespan and performance of oil sensors, consider the following best practices:

- Regular Inspection: Check sensor wiring and connectors during routine maintenance to prevent signal errors caused by corrosion or mechanical damage.

- Use High-Quality Parts: OEM-level or compatible sensors ensure accurate monitoring and long-term reliability.

- Track Sensor Data Trends: Monitoring oil pressure trends over time allows maintenance teams to plan preventive interventions before failures occur.

- Protect Against Harsh Conditions: Avoid exposing sensors to unnecessary mechanical stress or extreme environments beyond their specifications.

Implementing these practices will help businesses maintain reliable engines and prevent costly repairs.

Conclusion

Engine oil sensors are important for maintaining industrial engines, ensuring operational efficiency, and preventing unexpected failures. By providing accurate and timely oil pressure monitoring, these sensors allow operators to take proactive steps in protecting their machinery. Investing in high-quality sensors and sourcing from reliable suppliers are essential strategies for businesses seeking to minimize downtime, extend engine lifespan, and optimize maintenance costs.

For companies managing fleets of heavy machinery, a dependable oil sensor is more than a maintenance tool—it is a strategic investment that safeguards productivity, reduces operational risks, and supports long-term business growth. Reliable monitoring, proactive maintenance, and quality parts form the foundation of engine reliability in demanding industrial environments.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY