Why Excavator Engine Controller ECU Improves Machine Productivity ?

- jumi

- 2025-12-05

- 51

The ECU as the Foundation of Productive Excavator Performance

In the highly demanding construction and earthmoving industry, machine productivity is determined not only by hydraulic strength or engine power but increasingly by the precision of the excavator engine controller ECU. This compact but sophisticated unit regulates how the engine responds to load, how fuel is delivered, and how smoothly the machine transitions between operational modes. A stable ECU ensures that the excavator works at its intended performance curve, reducing hesitation, maintaining consistent output, and helping operators complete more cycles per hour. As job-site workloads intensify, the ECU becomes the strategic component that directly influences overall productivity.

How ECUs Optimize Fuel Burn and Power Delivery

A well-engineered ECU constantly analyzes real-time data from multiple sensors, including throttle position, crankshaft rotation, coolant temperature, and injection timing. Models such as KHR10023, KHR10025, KHR10026, KHR10027, and KHR10028 are designed to calculate the ideal fuel-air balance for any working condition. This helps prevent unnecessary power spikes, limits fuel wastage, and ensures that torque is delivered precisely when the operator needs it. For heavy digging, deep trenching, or rapid loading cycles, a responsive ECU significantly reduces cycle delays, allowing excavators to complete more work with less fuel and fewer mechanical interruptions.

Smoother Operation, Faster Cycles, and Reduced Component Stress

Machine productivity often depends on how quickly an excavator can accelerate, lift, swing, and reset for the next movement. An ECU with refined control logic offers smoother throttle transitions, stabilizes engine RPM, and minimizes vibration during start–stop operations. Operators using excavators equipped with KHR10026 or KHR10027 frequently notice faster response times and more predictable control during repetitive cycles. Beyond improving speed, a well-performing ECU reduces stress on key components, lowering the chance of overheating, irregular combustion, or hydraulic strain. This results in fewer breakdowns, longer component life, and significantly higher operational uptime across the machine’s working lifespan.

Improved Troubleshooting and Smarter Maintenance Decisions

Modern ECUs are also powerful diagnostic tools. They store fault codes, monitor abnormal sensor behavior, and warn operators before small issues grow into costly failures. Controllers like KHR10023 and KHR10028 offer precise data that mechanics can interpret quickly, shortening downtime and allowing repairs to be planned rather than forced by unexpected shutdowns. When maintenance becomes smarter and more predictable, excavator fleets stay productive and avoid delays that can disrupt entire project timelines.

Support for Environmental Standards and Advanced Technologies

Newer excavator models must comply with increasingly strict emissions standards. High-quality ECUs provide the internal management needed to reduce black smoke, stabilize combustion, and maintain clean engine output even under heavy load. Meanwhile, advanced ECUs such as KHR10025 and KHR10026 are engineered to support telematics, automation, and remote diagnostic systems. This ensures that excavators can integrate into intelligent fleet platforms, enhancing planning accuracy and improving long-term productivity through data-driven decision-making.

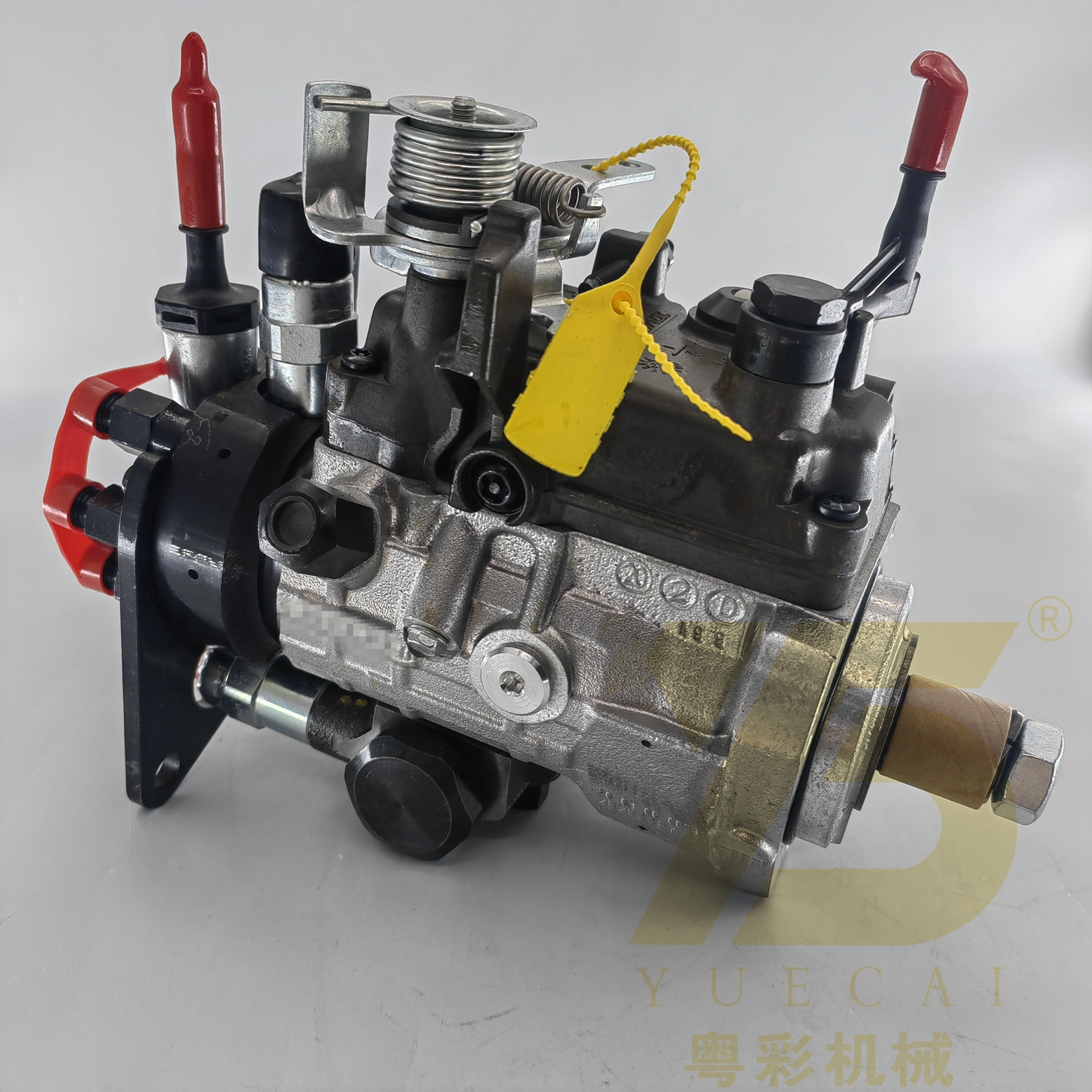

Delivering High-Performance ECU Solutions for Modern Excavators

Behind the growing demand for stable and intelligent engine control systems, YUE CAI provides a trusted range of excavator ECUs engineered for durability, precision, and long-term reliability. Whether customers need performance-tested models such as KHR10023, KHR10025, KHR10026, KHR10027, and KHR10028, or require guidance on troubleshooting and system calibration, YUE CAI supports global clients with professional technical knowledge and dependable quality assurance. By focusing on stable circuit design, strict quality control, and seamless compatibility, YUE CAI ensures that excavators achieve real, measurable productivity gains in every working cycle.

Conclusion: Productivity Begins with Intelligent Engine Control

Excavator productivity is no longer just a matter of raw horsepower; it depends on how intelligently that power is managed. A reliable engine controller ECU improves fuel efficiency, enhances cycle speed, stabilizes performance, and reduces downtime—all of which translate directly into higher machine output. With the continued advancement of digital control systems, high-quality ECUs supplied by YUE CAI will remain essential to maximizing productivity across modern construction sites. As the industry evolves, YUE CAI will continue delivering ECU solutions that enable excavators to work faster, smarter, and more efficiently than ever before.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY