Why Solenoid Valves Are Essential in Fluid Control Systems

- jumi

- 2026-01-29

- 13

Fluid control systems play a critical role in modern industrial equipment and heavy vehicles. From managing hydraulic pressure to regulating fuel and oil flow, these systems rely on precise, responsive components to ensure stable operation. Among them, solenoid valves stand out as one of the most essential control elements. Their ability to convert electrical signals into accurate mechanical action makes them indispensable in today’s automated and semi-automated systems.

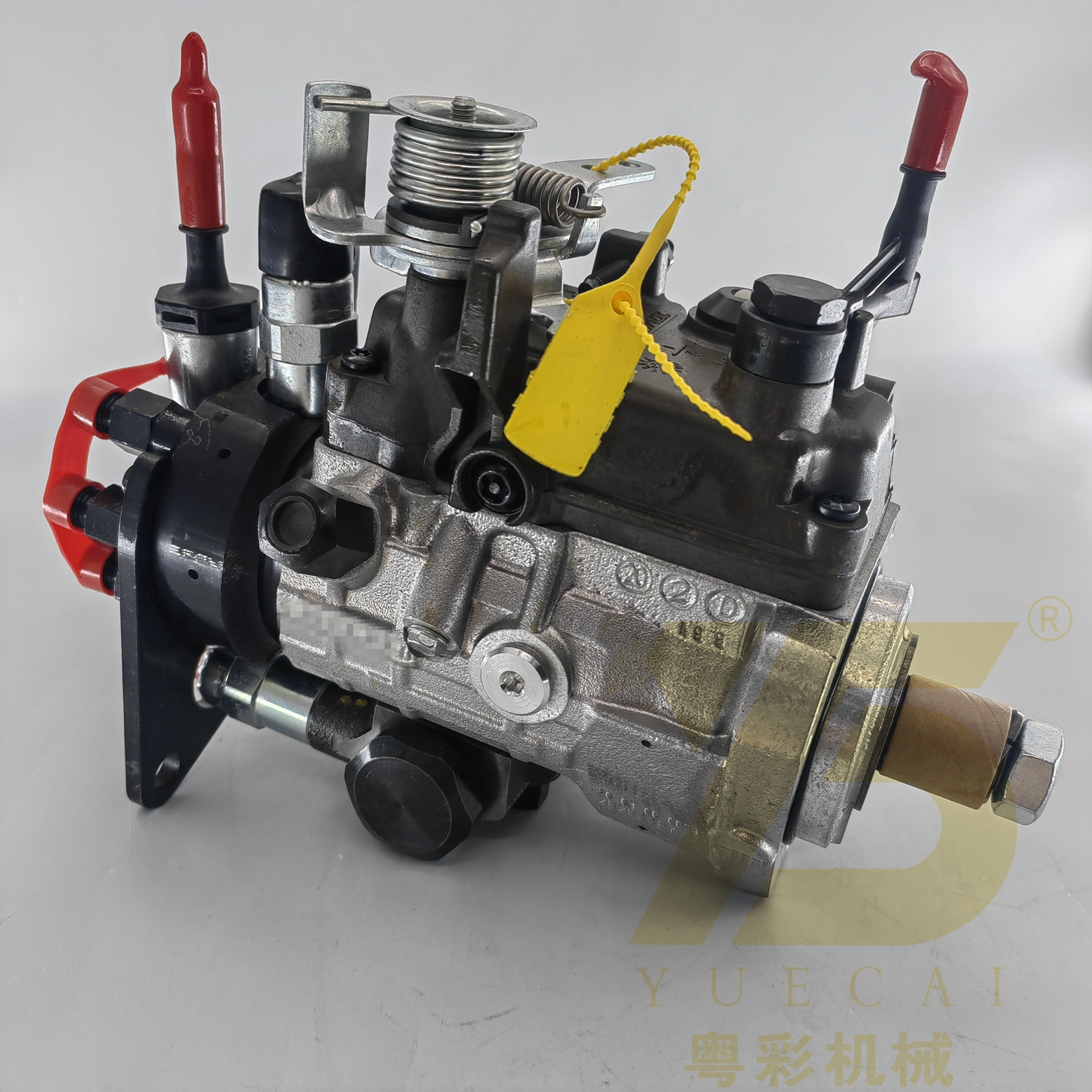

This article explores why solenoid valves are so important in fluid control systems, with a focus on heavy-duty vehicle applications, and how high-quality solenoid valves, such as the YUE CAI 12V / 24V solenoid valve, contribute to system efficiency, reliability, and long-term performance.

Understanding the Role of Solenoid Valves in Fluid Control

A solenoid valve is an electromechanical device designed to control the flow of liquids or gases within a system. When an electrical current is applied, the solenoid coil generates a magnetic field that moves an internal plunger. This movement opens or closes the valve, allowing or stopping fluid flow as required.

In fluid control systems, this mechanism enables precise on-off control or directional flow control. Compared with manual or purely mechanical valves, solenoid valves offer faster response times, better consistency, and easier integration with electronic control units. These advantages are particularly valuable in modern vehicles and machinery, where electronic control has become the standard.

Why Solenoid Valves Are Critical in Heavy Vehicle Systems

Heavy trucks and industrial vehicles operate under demanding conditions. Their fluid systems must handle high pressure, frequent cycling, and continuous operation over long periods. Solenoid valves are essential in these environments because they provide reliable control while maintaining operational efficiency.

In truck applications, solenoid valves are commonly used in systems related to fuel management, hydraulic control, lubrication circuits, and auxiliary functions. Precise fluid control helps optimize engine performance, reduce wear on components, and ensure safe operation. Without dependable solenoid valves, these systems would struggle to maintain the accuracy and responsiveness required for modern heavy-duty vehicles.

Designed for Demanding Applications

The YUE CAI solenoid valve is designed specifically for use in heavy truck fluid control systems. It is compatible with multiple truck series, including FH, FM, FMX, and NH platforms. This wide compatibility makes it suitable for a range of commercial vehicle configurations, reducing the necessity of multiple valve types across a fleet.

By supporting both 12V and 24V electrical systems, the solenoid valve offers flexibility in installation and application. Different vehicles and subsystems may operate on different voltage standards, and a dual-voltage solution simplifies parts selection while improving overall system compatibility.

Electrical Control and System Precision

One of the key reasons solenoid valves are essential in fluid control systems is their ability to respond instantly to electrical signals. In electronically controlled vehicles, sensors and control units constantly monitor operating conditions and send signals to actuators. Solenoid valves act on these signals with speed and accuracy, opening or closing fluid pathways at exactly the right moment.

This precise control helps maintain stable pressure levels, accurate flow rates, and consistent system behavior. In heavy trucks, such precision directly affects performance, fuel efficiency, and component longevity. A well-designed solenoid valve ensures that fluid movement matches system demands without delay or inconsistency.

Reliability Under Continuous Operation

Reliability is a critical requirement for any component used in commercial vehicles. Solenoid valves in fluid systems often operate continuously, cycling on and off thousands of times during normal use. Poor-quality valves can lead to sticking, leakage, or electrical failure, which may cause system malfunctions or unplanned downtime.

High-quality solenoid valves are engineered to withstand these operating conditions. The YUE CAI solenoid valve is supplied as a brand-new component and manufactured to meet the durability expectations of heavy-duty applications. Its design supports stable operation even under frequent use, helping reduce maintenance frequency and extend service life.

Simplifying Maintenance and Replacement

Another reason solenoid valves are so important in fluid control systems is their role in maintenance efficiency. When a solenoid valve is designed as a direct replacement part, it allows technicians to perform repairs quickly without modifying existing systems.

The YUE CAI solenoid valve is suitable for straightforward installation in compatible truck models. This ease of replacement minimizes labor time and helps vehicles return to operation faster. For fleet operators, reducing maintenance downtime is essential for controlling operating costs and maintaining productivity.

Supporting Efficient Fleet Operations

In fleet management, consistent parts availability and predictable performance are just as important as technical specifications. Solenoid valves that are readily available and consistently manufactured help ensure that maintenance schedules are not disrupted by supply delays.

Having a solenoid valve that is kept in regular stock allows repair shops and service teams to respond quickly to system issues. This reliability in supply supports smoother fleet operations and reduces the risk of extended vehicle downtime caused by waiting for replacement parts.

Enhancing Safety Through Controlled Fluid Flow

Safety is a fundamental consideration in fluid control systems. In heavy vehicles, improper fluid control can affect braking systems, steering assistance, or hydraulic functions. Solenoid valves help maintain safe operating conditions by ensuring fluids move only when and where they are intended to.

By responding accurately to control signals, solenoid valves prevent unintended fluid flow that could compromise system stability. This controlled behavior contributes to safer vehicle operation, particularly in demanding environments such as construction sites, long-distance transport, and industrial applications.

Versatility Across Multiple Systems

Solenoid valves are valued not only for their precision but also for their versatility. A single solenoid valve design can be used in various fluid systems depending on configuration and application requirements. In heavy trucks, this versatility allows engineers to standardize components across different systems, simplifying design and maintenance.

The YUE CAI solenoid valve’s compatibility with multiple part numbers and truck series reflects this versatility. It can function as a reliable solution across different applications while maintaining consistent performance standards.

Long-Term Value in Fluid Control Systems

When evaluating components for fluid control systems, long-term value is just as important as initial cost. A dependable solenoid valve contributes to lower total ownership costs by reducing failures, minimizing maintenance needs, and supporting efficient system operation.

By using a solenoid valve designed for heavy-duty use, operators can protect other system components from damage caused by pressure fluctuations or improper fluid control. Over time, this reliability translates into better performance and reduced operational risk.

Conclusion

Solenoid valves are an essential element in modern fluid control systems, especially in heavy vehicles where precision, reliability, and durability are critical. They enable accurate electrical control of fluid flow, support efficient system operation, and play a key role in safety and maintenance efficiency.

The YUE CAI 12V / 24V solenoid valve demonstrates how a well-designed solenoid valve can meet the demands of heavy truck applications. With wide compatibility, flexible voltage options, and reliable construction, it becomes a practical solution for fluid control systems that require consistent performance.

As fluid systems continue to evolve alongside electronic control technologies, solenoid valves will remain a foundational component. Choosing the right solenoid valve is not only a technical decision—it is an investment in system reliability, operational efficiency, and long-term performance.

Related Blogs

-

Infrastructure Boom Drives Global Surge in Excavator Parts Demand

-

The Future Trajectory of the Excavator Industry: A Glimpse into the Upcoming Trends

-

The Future of Excavation: How Technology and Sustainability Are Reshaping the Industry

-

Optimize Excavator Output with a Durable and Intelligent Engine Controller System

-

Smart Excavator Engine Controller Upgrades for Better Control and Machine Stability

Give Us What You Need

SUBSCRIBE

INQUIRY